Ideal applications

1.High destruction efficiency requirement.

2.High emission concentrations.

3.Multi-source emission with different working conditions.

4.Halogenated or salt-laden gas,

5.Particulates or viscous substances in the airstream.

6.Process heating needs.

7.High operating stability requirement.

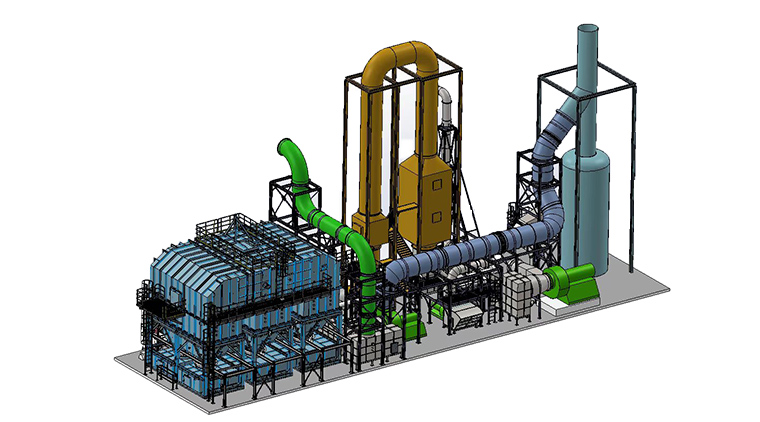

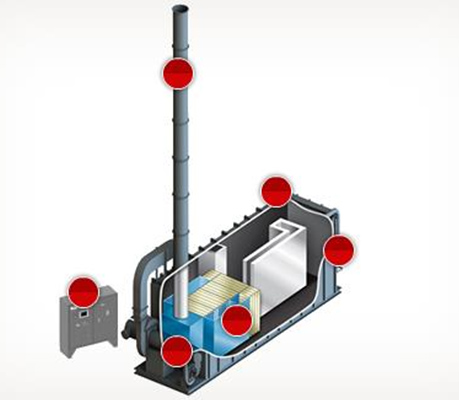

Diverse Options

We provide custom design options to meet regulations and energy saving requirements.

1. mixed combustion oxidizer with waste gas and waste liquid.

2. Specialty oxidizer designs for salt-containing gas, liquid and halogen bearing corrosive applications.

3. Secondary heat and Energy Recovery Solutions for process heating needs.

4. Quench, Acid or alkaline gas scrubber module with a completely integrated control system.

5. SCR and other denitration module.

6. Wet desulfurization module;

7. dust removal system.

.png)