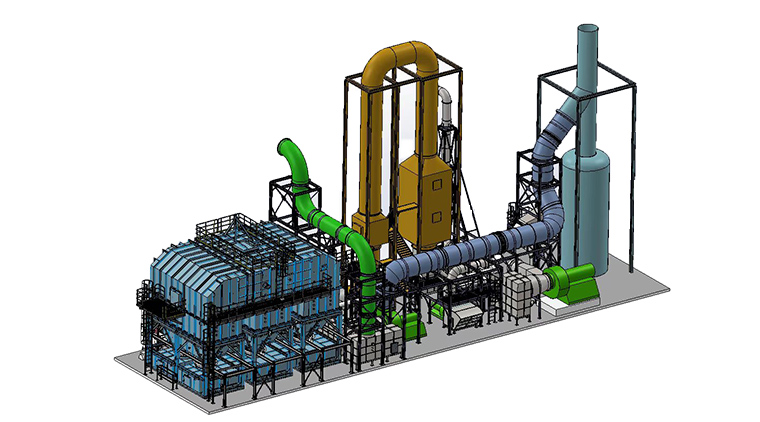

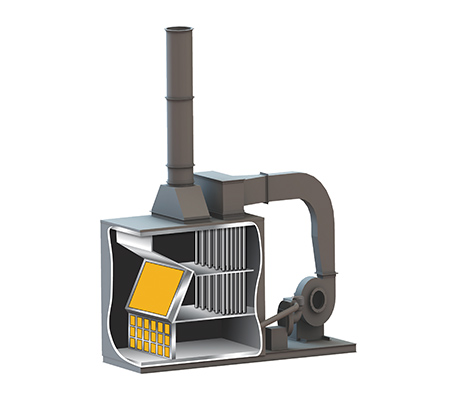

Ideal applications

1.Low process volume, medium to high emission concentration.

2.Strict limitation on gas or power.

3.VOCs laden process gas with pollutants can be destroyed by the catalysts.

4.Fully characterized process streams with no catalyst poisons, particulates, adhesive substances or masking agents.

.png)